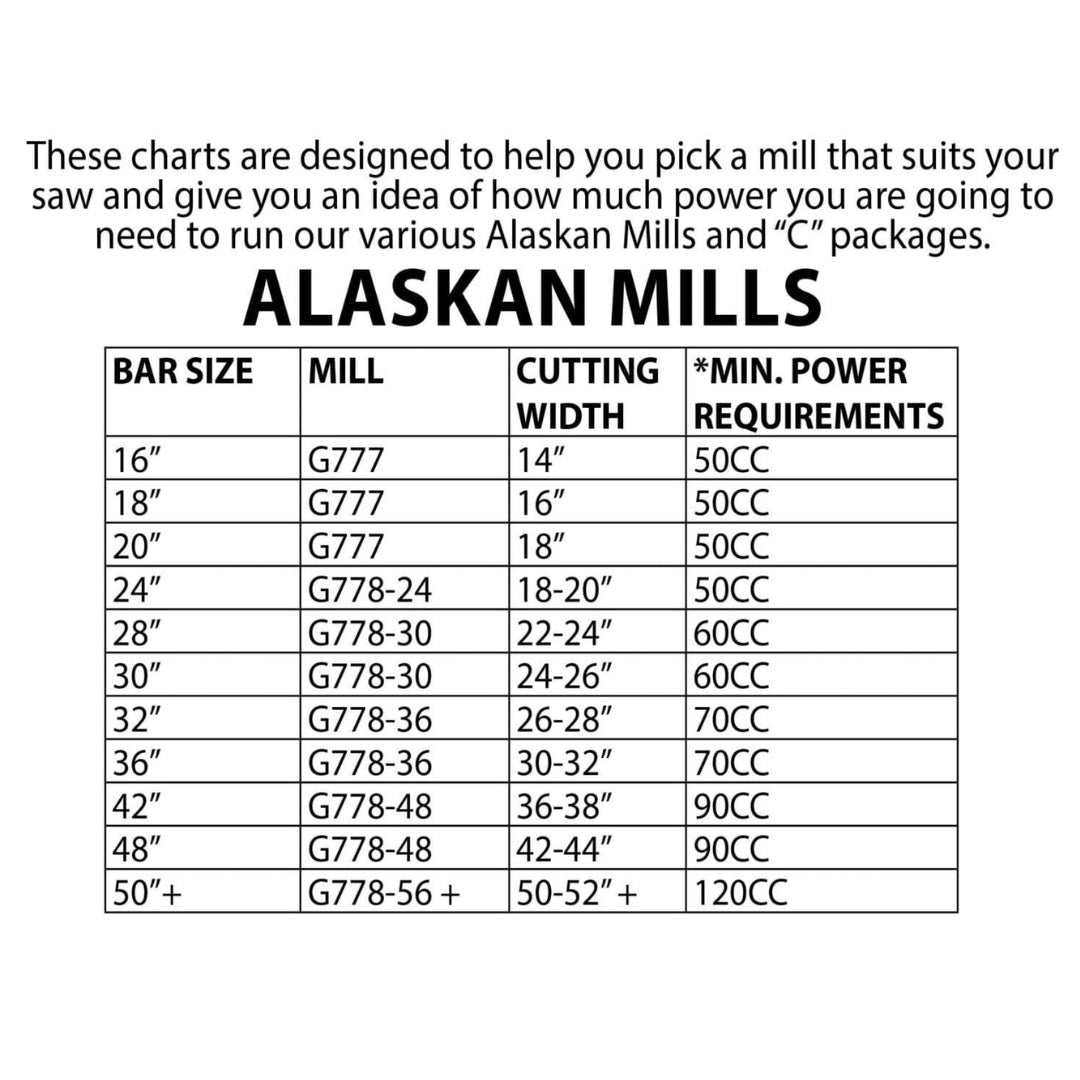

Granberg's versatile, heavy-duty chainsaw lumber mill precisely cuts planks and beams up to 44" wide and 1/2" - 13" deep. This mill is perfect for woodworkers, arborists, sawyers and homeoweners. For use with chainsaws with bars of 48" or less, OR double-ended bars of 56" or less and 90cc or more diplacement.

GRANBERG SAW MILL FAQs

VIDEO: Milling Tips for first-time users

★ What are the chainsaw size and power requirements for Granberg Saw Mills?

Why should I use "Ripping Chain" with my saw mill?

How do I find the right Ripping Chain?

Do I have to use wedges with the Granberg Saw Mill?

Can I put a larger mill on a smaller bar?

How do I make lumber with a Granberg Saw Mill?

Free shipping

on orders over $100

Right Part Promise

when provided with model info

No sales tax

outside Washington and Wisconsin

- Choosing a selection results in a full page refresh.